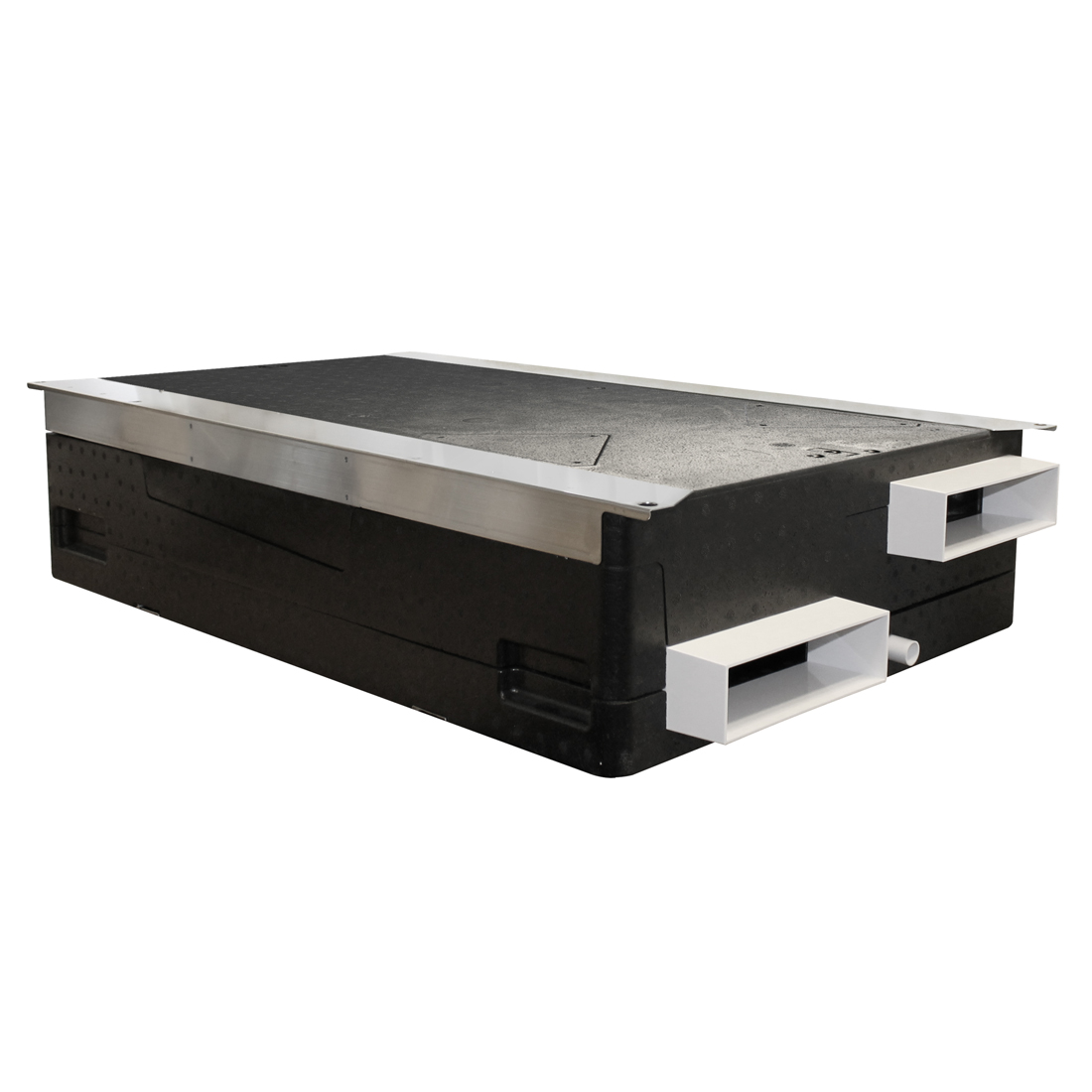

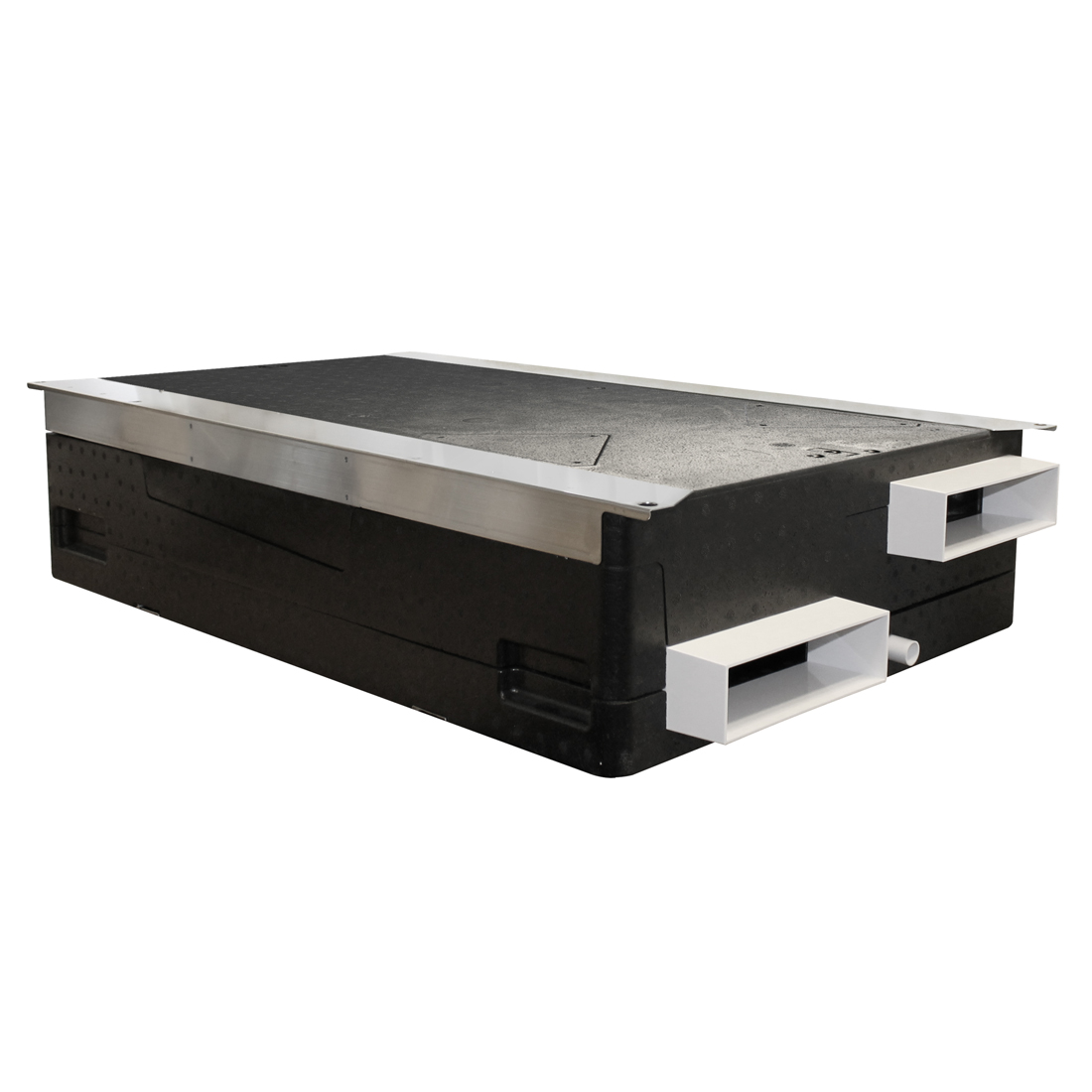

Vent Axia Sentinel Kinetic 200ZPH Horizontal Heat Recovery Unit

Vent Axia Sentinel Kinetic 200ZPH Horizontal Heat Recovery Unit

Product Part Number

Sentinel Kinetic 200ZPH Horizontal Heat Recovery Unit - 407162

Description

Vent Axia Sentinel Kinetic 200ZPH is a horizontal ceiling mounted whole house heat recovery system with up to 86% heat exchange efficiency. Specifically designed for new build constructions with a high level of insulation.

The Lo-Carbon Sentinel Kinetic Horizontal 200ZPH meets the latest requirements of the Building Regulations ADF and ADL for whole house system ventilation: System 4 - Continuous mechanical supply and extract with heat recovery.

Vent Axia 200ZPH is suitable for house sizes of up to 140m2

Filtration

This unit requires 2 x G3 filter

Controllability

The Lo-Carbon Sentinel Kinetic Horizontal models have two fully adjustable speeds and a purge setting (maximum airflow). Supplied with the unit is a digital controller that can be used to pre-set the speeds to any required airflow within the performance range.

Boost can be achieved with almost any type of sensor or switch including momentary.

Integral Humidity Sensor

The integral humidity sensor increases speed in proportion to relative humidity levels, saving energy and reducing noise. The sensor also reacts to small but rapid increases in humidity, even if the normal trigger threshold is not reached. This unique feature ensures adequate ventilation, even for the smallest wet room. The night time relative humidity setback feature suppresses nuisance tripping as humidity gradually increases with falling temperature

Construction

Constructed of galvanised steel and is fully insulated

Motors

The unit has 2 x low energy, high efficiency EC/DC motors

Installation

The Sentinel Kinetic Horizontal models designed to be horizontally mounted under a slab, with access for servicing and maintenance from below. When mounted in an unheated area ducting must be insulated. 200 ZPH models are 200mm deep, including condensate and mounting bracket. The Condensate drain is through the 'atmosphere' end of the unit. Using the fittings supplied, the final condensate connection is made outside the unit and can be completed after installation. Electrical and control connections are also made on the outside of the unit.

Accessories

In addition to a choice of compatible ducting systems a full range of controls, sensors, in-line silencers, floor/wall/ceiling inlet and outlet diffusers are available to complete the installation.